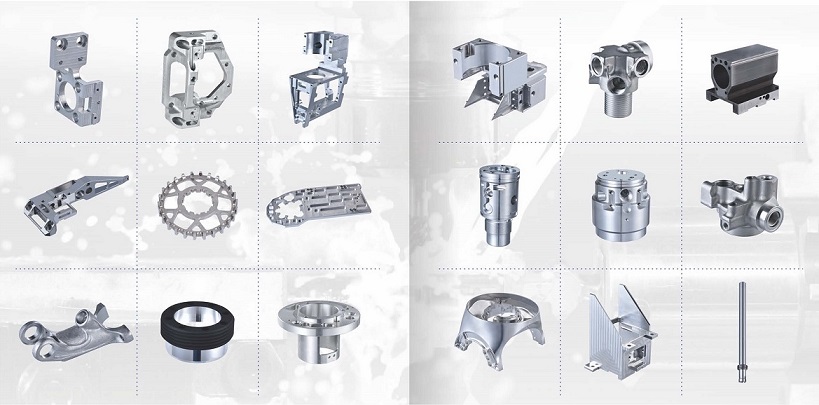

Rapid Prototyping

Already finished your design in china, need samples for testing or approval?

No problem, we can handle this. For each order of your, we always start the mass stamping production upon your approval of samples. Sometimes, if the schedule is not so tight and we already got the right material stocked, we may not charge you. Anyway, it depends on the total cost. We will try to offer you the parts at a reasonable price. Just send your original samples or drawings to us and we will see to the rest.

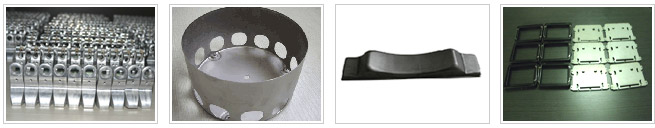

How can you do it?

For custom metal stamping parts in china, we use wire cutting or simple tooling. And for screw machine products & turned parts, we usually use traditional machining, metal stamping or on automatic screw machine with new tooling.

Does secondary operations and plating surface treatment apply for the parts?

Yes, valued added secondary processing is available. And heat treatment and plating is also applied.

How much time do you need to make prototypes or samples for me?

7-15 days, it depends on the workload and the complex of the parts. If the parts need secondary processing and surface treatment, it may take 3-7 days more.

Please specify the prototype or sample quantity you need for testing or approval when contacting us. Then we can calculate the charges and lead time for you.

Note: for custom metal stamping, as we do it by wire cutting or using simple metal stamping dies, the samples may not the same as your drawing show. And we will let your know the small differences before prototyping. Usually that kind of small differences won't exist in mass production with the the formal tooling completed.

-

Warmly welcome Dr. Torsten Becker and Lance Lan from Germany ...

-

New customer from Mexico who namedIsaac Smeke will be visitin...

-

Warmly welcome Mr Andy from UK visiting our factory check his...

-

Warmly welcome Mr Anwar Master from The Kingdom of Bahrain vi...