Nagualmetal CNC Machining in china

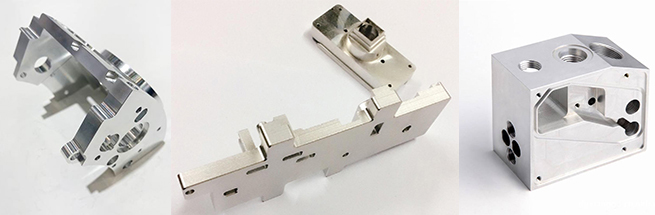

Branch of Nagualmetal is a specialist China manufacturer and supplier offering the full range of CNC/EDM engineering services, comprising CNC Machining, CNC Milling, CNC Lathe Turning, EDM Wire Cutting and EDM Eroding. Computer Assisted Manufacturing (CAM) programs are run on customer 2D or 3D CAD data files. CAM programs are then directly downloaded to one of our CNC machines for automated machining.

Our lead times are fast, depending on the nature and volume of work. Automatic tool changers, high speed spindles, and fast feed rates allow us to machine components efficiently and accurately.

A wide range of materials such as aluminium, steel, hardened tool steel, stainless steel cast iron, brass, copper, polycarbonate, ABS, acrylic, PET, nylon and more can be machined to suit your needs.

● Materials for CNC Precision machining parts

We can process product materials are:

An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from 1050-7475), commonly used are: 2011,5052,6061,7075, etc.

(2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000

(3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades (JIS grade corresponds to the basic, together with the SUS can): 201,301,303,304,314,316,420,430,630

Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15)

● CNC Precision machining parts accuracy

Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm

About CNC turning

-

Warmly welcome Dr. Torsten Becker and Lance Lan from Germany ...

-

New customer from Mexico who namedIsaac Smeke will be visitin...

-

Warmly welcome Mr Andy from UK visiting our factory check his...

-

Warmly welcome Mr Anwar Master from The Kingdom of Bahrain vi...