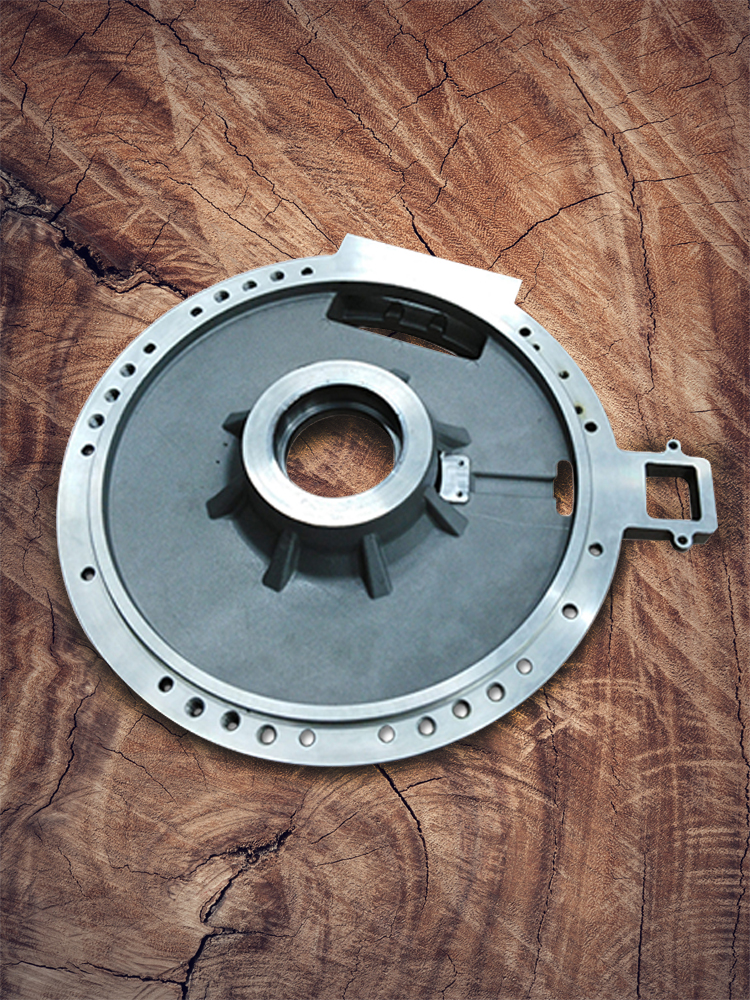

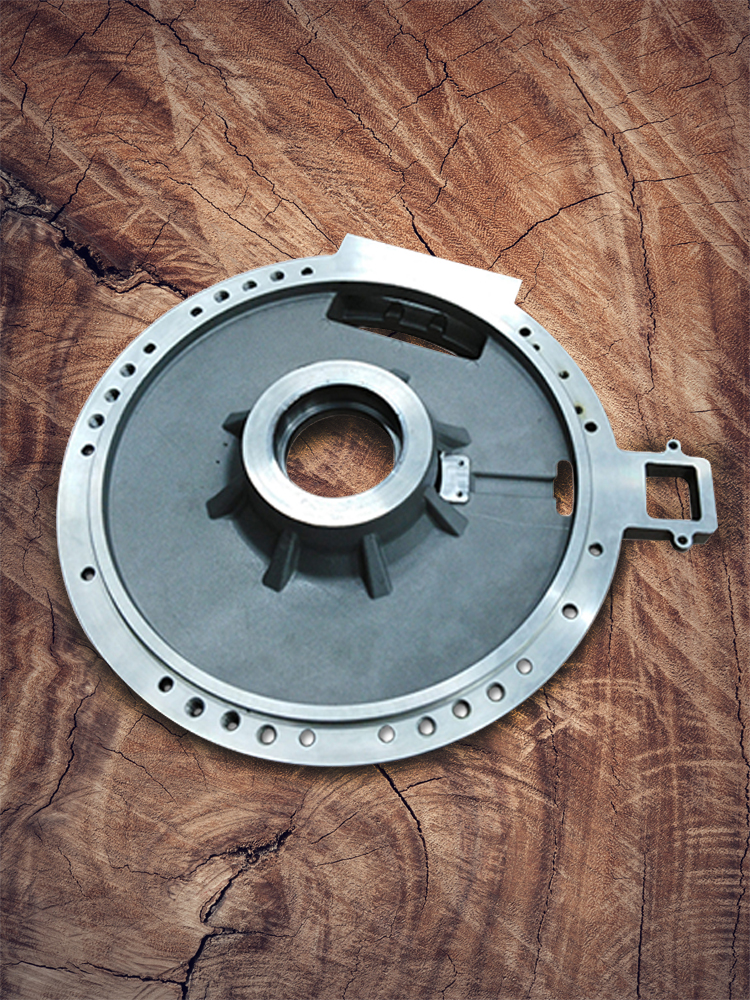

DIE CASTING

Die casting is a manufacturing process in which molten metal is poured or forced into steel molds. The molds—also known as tools or dies—are created using steel and are specially designed for each project. This allows each component to be created with accuracy and repeatability. Aluminum, zinc, and magnesium are the most commonly used die casting alloys.

Other benefits include:

Variable wall thicknesses

Tighter tolerances

Fewer steps from raw material to finished part

Fast production cycle times

Reduction in material scrapLong tool life, especially for zinc and magnesium

Aluminum Die Casting and Zinc Die Casting Capabilities

In zinc, we have 22, 44, 66 and 88 Techmires along with conventional zinc die casting machines.

In aluminum, we have from 500 to 1000 ton cold chamber machines.

In addition, we also offer the following:

CNC Machining

Shot Blasting

Heat Treating

Light Assembly

Vibratory Finishing

latest news

-

Warmly welcome Dr. Torsten Becker and Lance Lan from Germany ...

-

New customer from Mexico who namedIsaac Smeke will be visitin...

-

Warmly welcome Mr Andy from UK visiting our factory check his...

-

Warmly welcome Mr Anwar Master from The Kingdom of Bahrain vi...